Perhaps you’ve seen a type of lumber for sale known as “soft maple,” and were wondering: what’s the difference between between this Soft Maple and Hard Maple? Just how soft is it? Why does it cost about half as much as Hard Maple? How can I tell the two apart?

Well, here are the answers:

HARD VS. SOFT: WHAT’S THE DIFFERENCE?

The term “soft maple” does not refer to any specific species of maple, but rather, it’s a broad term which includes several different species of maple. The term “soft maple” is merely used to differentiate these species from hard maple.

Hard Maple, on the other hand, typically refers to one specific type of maple species: Acer saccharum. Hard maple is also known as rock maple or sugar maple, (this is the same tree which is tapped to get maple syrup). Besides this one species of maple, the only other species that are sometimes considered in the grouping of hard maple in the United States are black maple (Acer nigrum) and Florida maple (Acer floridanum). But these species are far less commonly seen commercially, and they are both so closely related to hard maple that some even consider them to be sub-species of the same tree, classifying them as Acer saccharum subsp. nigrum. and Acer saccharum subsp. floridanum, respectively.

Depending on where you live, different species might be sold as soft maple. For instance, if you live in Oregon, the soft maple that you buy (if it has been harvested locally) will likely be bigleaf maple, while those living in the eastern United States may actually be buying red maple or silver maple. (And just as citizens of both the east coast and the west coast each like to assert the superiority of their own respective region, there is almost a rivalry between bigfleaf maple advocates on the west coast, and red maple fans on the east coast.)

Some of the most common species of maple that fall under the grouping of soft maple are:

- Bigleaf maple (Acer macrophyllum)

- Box elder (Acer negundo)

- Red maple (Acer rubrum)

- Silver maple (Acer saccharinum)

- Striped maple (Acer pensylvanicum)

Each of these maples have their own characteristics regarding strength, hardness, weight, etc. But overall, they are not as hard nor as strong as hard maple; though for a more exact comparison, continue to the data found in the next section.

HARDNESS OF MAPLES COMPARED

It should be obvious that hard maple is harder than soft maple, but you may be wondering how much of a difference there is between the two. Will soft maple simply collapse like a polystyrene cup as its “soft” name implies?

The good news is that for many purposes, soft maple will be hard enough to be used in place of hard maple. Even though it is referred to as soft maple, it is only soft in relation to hard maple.

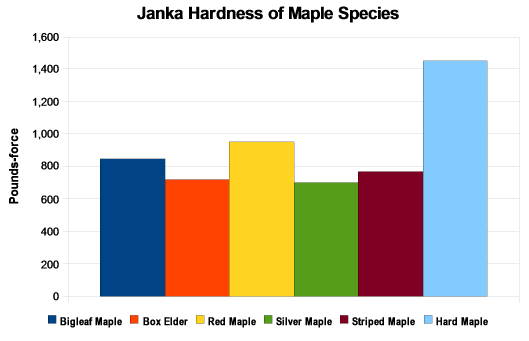

A common measurement of wood hardness is the janka hardness test. The test measures the amount of force required to embed a .444″ diameter steel ball halfway into the wood. The results for each of the maple species are shown in the chart below.

Now it may look like hard maple is heads and tails above the rest (and to a certain extent, it is), but for reference, black cherry has a janka hardness of 950 lbf (the same as red maple), and black walnut is rated at 1,010 lbf. Also note that black maple (not pictured), isn’t quite as hard as its close relative, hard maple, and ranks in the mid-range, with a hardness of 1,180 lbf.

Taking the hardness data within context of other hardwoods, soft maple may be used as a valid substitute for hard maple in most situations where a hardwood of moderate density is called for. In addition, soft maple is slightly easier to work with, and won’t dull cutting edges as quickly, or burn as readily when being shaped as hard maple.

The main instances where you would want to stick with hard maple would be in applications where hardness and strength are important, such as: butcher blocks, flooring, workbench tops, etc. Hard maple (1,450 lbf janka) is roughly twice as hard as soft maple (700-950 lbf janka)—primarily because it tends to grow about half as fast as most other soft maple species. (And to a great extent, this also accounts for the difference in cost between the two types of maples as well.)

TELLING THE TWO TYPES OF MAPLE APART

Unlike the task of telling red and white oak apart, sorting between hard and soft maple isn’t quite as clear-cut. Hard maple, based on simple outward appearances, looks very similar to soft maple, and in general is tough to tell apart in finished pieces. When attempting to sort out different maple species, it’s important to keep in mind the limitations and obstacles that are present in our task. (Please have a look at The Truth Behind Wood Identification to approach the task in a proper mindset.)

There are four main ways that can help you tell hard maple from soft maple.

1. WEIGH THE WOOD

In my opinion, getting an accurate density value is the best way to practically evaluate maple. Janka hardness has been shown to be directly related to density. Even if a board is technically from a “soft” maple species from a biological standpoint, if it happens to be as dense as hard maple, then the point is moot (as it will also be as hard as true hard maple as well). Likewise, if a piece of verified hard maple should happen to be as lightweight as a piece of soft maple, then most of the rationale for using hard maple is irrelevant. (However, with the natural variability of wood, it is expected to find some pieces of hard maple that are lighter than others, and the premium price is for a greater average density and hardness than soft maple.)

A brief sidenote on the “fingernail test”

A very crude test that you can perform on milled boards before they are put into final use is sometimes called the fingernail test. Basically, you find a crisp edge of the wood, and with your fingernail you try to push in as hard as you can and see if you’re able to make a dent in the wood.

With hard maple, virtually no dent should be left with your fingernail, yet soft maple will be more likely to be dented. Yet since everyone’s fingernails and strength is different, this should only be considered a very crude means of testing when other methods/tools are not available. A much better and more accurate way of testing the wood, you can take measurements of the board in question, and then weigh it to get an estimate of its density. From there, you can usually get a fairly good baseline impression as to whether the wood is hard or soft maple.

Whenever you are weighing wood, remember that on average wood density has about a 10% coefficient of variation, which means that a wood could easily be plus or minus 10% of the average weight and still be considered “typical” for the species.

| MAPLE TYPE | AVERAGE DENSITY(in lbs/ft3) | DENSITY RANGE(+/- 10%) |

| Hard maple | 44 lbs/ft3 | 39.6 to 48.4 lbs/ft3 |

| Black maple | 40 lbs/ft3 | 36 to 44 lbs/ft3 |

| Bigleaf maple | 34 lbs/ft3 | 30.6 to 37.4 lbs/ft3 |

| Box elder | 32 lbs/ft3 | 28.8 to 35.2 lbs/ft3 |

| Red maple | 38 lbs/ft3 | 34.2 to 41.8 lbs/ft3 |

| Silver maple | 33 lbs/ft3 | 29.7 to 36.3 lbs/ft3 |

| Striped maple | 32 lbs/ft3 | 28.8 to 35.2 lbs/ft3 |

It should be noted that these are the average weights for the given species, and depending on the growing conditions of the tree, these numbers can easily be higher or lower. (For instance, red maple overlaps with both black and hard maple in its density range, so weight alone can’t be used to identify the wood—especially if only one or two small samples are weighed.) Also, the density is given for wood that is at 12% moisture content: having a substantially higher or lower moisture content can alter the wood’s weight accordingly.

If you have a small postage scale, or an accurate digital scale, you may be able to get relatively accurate measurements. (Bathroom scales with only 1/2 pound increments are usually far too crude a measurement to give reliable results.) Generally, the larger the sample to be weighed, the more accurate the results. Simply weigh the wood in question, and then carefully measure all dimensions to find its total volume. Remember, Volume equals Length x Width x Height: (V = L x W x H).

Calculating density

Let’s say we have a piece of maple that is 24 inches long, 8 inches wide, and .75 inches thick. This means that the total volume is 144 cubic inches, since 24 x 8 x .75 = 144.

Next, we’ll assume we’ve weighed the board, and found that it weighs 3 pounds, 8.0 ounces (or 3.5 pounds). So our board’s density is 3.5 pounds per 144 cubic inches. The only problem is that we need to convert our measurements to the units that we are trying to find in the chart above: pounds per cubic foot.

There are 1728 cubic inches in a cubic foot, (12 x 12 x 12), so to find our multiplier, we divide the 1728 cubic inches by the 144 cubic inches of our board, and get a multiplier of 12. (Most measurements won’t come out to a perfectly even number, but I chose a board with easy dimensions to make it a little simpler to calculate.)

So to convert our board from 3.5 pounds per 144 cubic inches to pounds per cubic foot, we simply multiply both sides by the multiplier we found in our previous step: in this case, it’s 12. So multiplying things out, we find that our board is 42 pounds per 1728 cubic inches (or one cubic foot). Taking this calculation (42 pcf), and looking at the table above, it would appear that in all likelihood, this board is indeed Hard Maple.

2. LOOK AT THE ENDGRAIN

It can be tough to discern the differences between the maples, and there are a number of subtle differences that may not be reliable enough on their own to distinguish the two types, but they still serve as indicators that can help point toward an identification:

- Hard maple tends to be of a lighter, more uniform color, while soft maple tends to be a bit darker, with red, brown, or gray streaks. (This is a good rule of thumb, but in reality, all types of maple can have a very broad range of color variation.)

- Since hard maple grows slower than soft maple, the growth rings on hard maple will generally be closer together than those of soft maple. Since a lot depends on growing conditions for each individual tree, this is not a foolproof way of distinguishing the two, but is a good reference point. It’s possible for soft maple to have tighter growth rings, but it’s much less likely for hard maple to have widely spaced growth rings on the endgrain (3/8″ or more).

With a 10x magnifier, look at a clean and sanded (to at least 220 or 300 grit) view of the endgrain. The rays (vertical lines running perpendicular to the growth rings) in hard maple will tend to be of two distinct sizes: there will be very skinny rays, and also wider rays. Soft maple exhibits a much narrower range of ray widths, with most being uniformly thin.

3. USE A CHEMICAL TEST

Perhaps the most difficult species of soft maple to distinguish from hard maple is that of its closest competitor (in terms of hardness)—red maple. Thankfully, a solution of ferrous sulfate (FeSO4) can be used to distinguish between a few types of maples, especially between red maple and hard maple.

Ferrous sulfate, sometimes called iron sulfate, may be obtained locally through chemical supply stores, but it is typically only sold in bulk quantities, making such a small project prohibitively expensive. However, some online retailers like Amazon have the chemical for sale in much smaller quantities.

While some sources recommend a “saturated” solution of ferrous sulfate, this is usually needless—even very small quantities of ferrous sulfate mixed in water are enough to give pronounced reactions. If a completely saturated solution of ferrous sulfate is applied to the wood surface and allowed to dry, a layer of pale crystallized material will be deposited, obscuring the color results on the wood surface beneath. A good intermediate solution of ferrous sulfate is given below.

Recipe for Ferrous Sulfate Solution for Testing Maples

1/2 cup of water

1/2 teaspoon ferrous sulfate

Directions: Stir in ferrous sulfate and allow to stand for several minutes. Solution should take on an amber color.

Once the solution is mixed and ready, simply brush a liberal amount onto the wood surface, and wait for a color to develop. (If only a thin layer is brushed on, or if the wood rapidly absorbs the solution, it’s recommended to reapply a second layer within about a minute of the first application.) A color change can be seen within about 10 minutes, but it’s best to wait about an hour for the full color to develop before attempting to determine the outcome.

Red maple gives a deep, inky blue/black color, while hard maple results in a paler bluish green color. In addition to these two main woods, different species of maple and other lookalikes (such as birch, dogwood, etc.) will give different reactions.

Other hard maples turning pale blue/green:

- Black maple

- Field maple (from Europe)

Other soft maples turning pale blue/green (false positives):

- Silver maple

- Bigleaf maple (ambiguous, slightly darker than Hard Maple)

- Sycamore maple (from Europe)

Non-maples turning pale blue/green:

- Birch (very pale coloration)

Non-maples turning dark blue:

- Flowering dogwood

Maples species that are non-responsive:

- Box elder (neutral, no discoloration)

4. LOOK AT THE LEAVES ON A LIVING TREE

Under most circumstances, it’s usually possible to determine with a fair degree of certainty whether any given piece of wood is hard or soft maple using all the previous tips; yet it can be nearly impossible to determine the exact species of soft maple just by looking at the wood, or even weighing it.

To achieve such refinement in identification, one of the best things to do is look at the leaves of the maple tree in question. (This option is obviously only available if you still have access to the living tree, and you are contemplating having it milled into lumber.) Below is a chart showing illustrations (and some scans) of maple leaves of various species, along with descriptions of their size and characteristics. While there are literally thousands of species of maple in the world, with numerous hybrids and cultivars, the list below should help to identify the most common ones.

NAME/DETAILS

FOLIAGE ILLUSTRATION

LEAF PHOTO

Hard maple—The classic shape that is most often associated with a maple leaf. Leaves typically have either 5 or 7 lobes, with vivid autumn coloring ranging from yellow to purplish red.

Black maple—Very similar to hard maple, black maple leaves typically have only 3 lobes, with much shallower notches between them. Leaves of black maple also tend to be thicker than those of hard maple.

Bigleaf maple—Just as its name implies, this species of maple has the largest leaves of any maple, with a leaf size of 6 to 12 inches (15-30 cm) across. Bigleaf maple is common in the Pacific northwest United States.

Box elder—Distinct from other maple leaves, box elder is sometimes called “ash-leaved maple,” since its leaves look closer to ash than maple.

Red maple—Leaves can vary in form, and look similar to either striped maple or hard maple—though with a more jagged edge. Red maple trees have distinctive red flowers, twigs, seeds, and red leaves in the fall.

Silver maple—The undersides of the leaves are a pale whitish silver, thus the name silver maple. Leaves have deep notches between the lobes which help to tell them apart from the shallower notches of hard maple

Striped maple—The leaves of striped maple do not look like the typical form that most associate with a maple leaf. The bark of this tree has green, white, and/or brown vertical stripes along the trunk.

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.